Denver Pipe Leak Detection & Repair, Burst or Leaking Sewer, Water, Drain or Copper Pipe, What To Do?

Turning off the water supply before initiating pipe repair in Denver is paramount to prevent further damage and facilitate repair. Tools such as plumber's tape, putty, and clamps often act as temporary but essential solutions for managing leaks in the interim. These measures prove handy for small leaks but emphasize the importance of planning for and eventually implementing more permanent repairs to avoid long-term issues and ensure water integrity.

When dealing with water and drain leaks, mastering pipe repair involves understanding various materials and methods—from applying epoxy putty to using a repair clamp with a neoprene rubber patch for more significant ruptures 2. As leaks can significantly disrupt a household's functionality, identifying the source of the leak and effectively applying a temporary fix is crucial, as is recognizing when to seek professional help for a lasting solution. We will show you the essential tools, materials, and guidance for repairing different types of pipes in Denver, ensuring Denver homeowners are well-equipped to manage these common issues.

How to Find the Leaking Sewer, Water, Drain, and Copper Pipes

Knowing what to look for and where to look is half the battle to find leaks. The signs of a leaky sewer or water pipe can range from the obvious to the subtle. For sewer pipes, a foul odor is often a telltale sign. Water and drain pipes might show signs of leaks through damp patches on walls, ceilings, or floors, or you may notice a decrease in water pressure.

Copper Pipe Leaks

Commonly used for water supply lines, can develop pinhole leaks that are difficult to spot. These leaks often show green or white corrosion outside the pipes. It's essential to inspect exposed pipes in your home regularly for any signs of moisture or discoloration.

In some cases, more advanced detection methods, such as special listening devices or moisture meters, may be needed to pinpoint the location of hidden leaks. But if you know where and what to look for, the signs are often visible to the naked eye.

Signs of a Sewer Pipe Leak

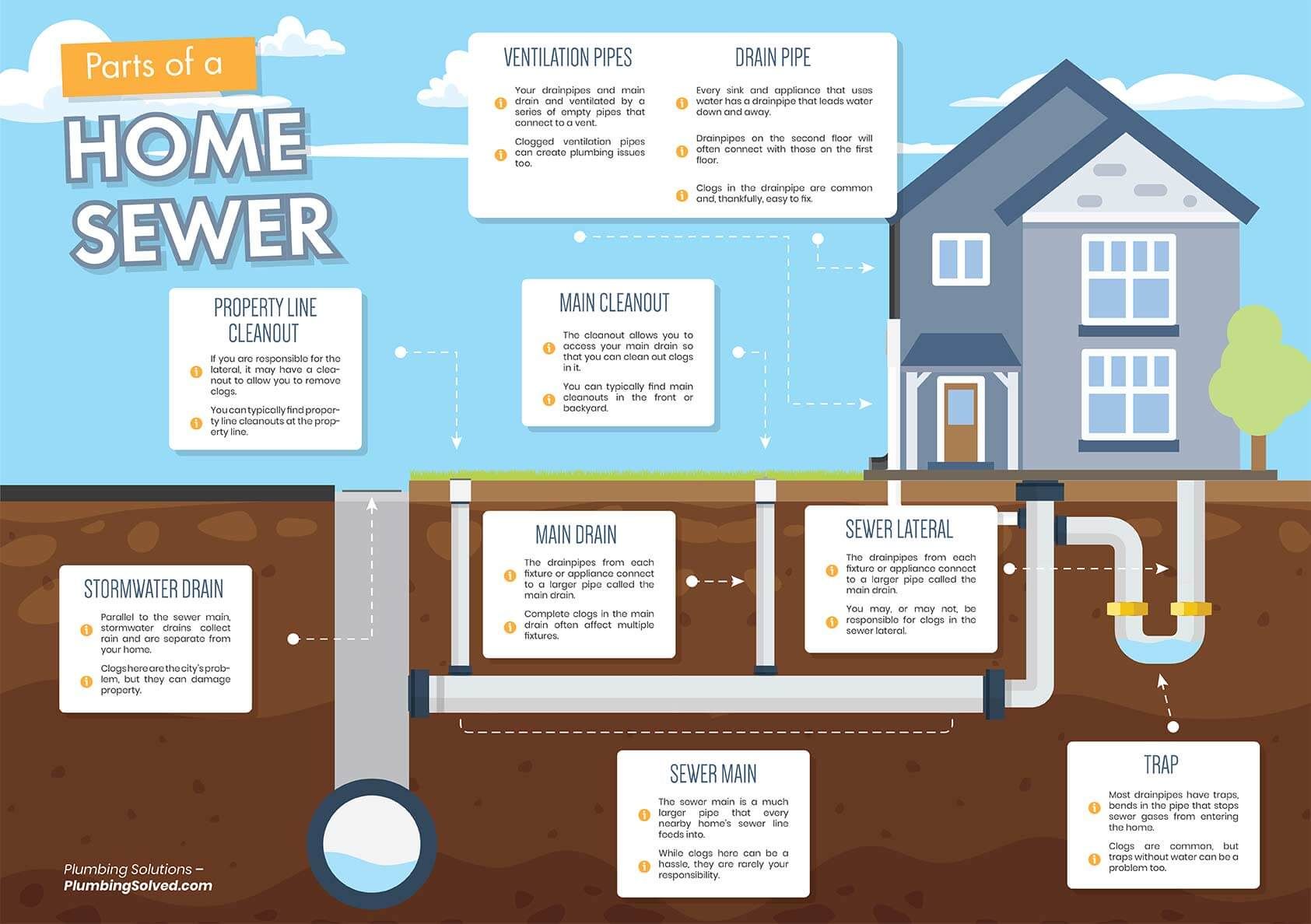

The first step in detecting a sewer leak is to recognize the signs. Apart from the smell, you might notice a lush patch of grass in your yard, indicating a sewage leak underground. Inside the house, look for signs like slow-draining toilets and sinks or the sound of constantly running water.

Inspecting the Sewer Cleanout

The sewer cleanout is an access point to the sewer line, usually equipped with a cap or plug. By removing the cap, you can inspect for any backup or overflow, which indicates a blockage or leak in the sewer line.

A dye test involves adding a non-toxic dye to the toilet or drain. You leak if the dye appears outside where it shouldn't. This method is simple yet effective for identifying sewer leaks that are otherwise challenging to locate.

Visual Inspection for Wet Spots

Start with a thorough visual inspection of your home, including the basement, crawl spaces, and around the perimeter. Look for wet spots on the ground, walls, or ceiling. These spots are often an indicator of a leak in a nearby water pipe.

Monitoring the Water Meter

Another technique is to monitor the water meter. Turn off all water-using appliances and fixtures, and watch the meter. If it continues to move despite everything being off, there's likely a leak in your system.

Listening to the Sound of Running Water

Sometimes, the sound of running water can lead to the source of a leak. Listen carefully for any hissing or dripping sounds at night or during quiet times within walls or under floors, which could point you to a leaky water pipe.

Checking for Obvious Signs of Damage

Begin by checking for signs of damage to drain pipes, such as cracks or breaks. These are usually visible in exposed piping under sinks, basements, or crawl spaces.

Using Smoke Tests

A smoke test works for less apparent leaks. This smoke test involves blowing smoke into the drain system and watching for where smoke exits. A smoke test is a clear sign of a leak and can be especially useful for finding leaks in vent pipes.

Applying Pressure Tests

Pressure tests involve plugging the system and adding air or water pressure to see if it holds. A pressure loss would indicate a leak and further investigation would be needed to locate its exact position.

Looking for Corrosion and Discoloration

Copper pipes can develop leaks due to corrosion. Look for greenish-blue stains or discoloration on the pipe's surface, which are signs of corrosion and potential leaks.

The Pinhole Leak Challenge

Due to their small size, detecting pinhole leaks in copper pipes can take time and effort. One method is to dry the pipe and then wrap it with a tissue or paper towel. After some time, check the paper for any signs of wetness indicating a pinhole leak.

Basic leak detection Tools

I recommend that every homeowner have several essential tools for leak detection. These include a flashlight for inspecting dark areas, a tape measure, and a moisture meter for detecting dampness in walls and floors. Try using a screwdriver, and a pipe wrench may also be needed to remove fixtures or panels for inspection.

Advanced Leak Detection Equipment

Specialized tools are available for more advanced leak detection. Acoustic listening devices can detect the sound of water escaping from pipes, and infrared cameras can identify temperature differences caused by dampness. These tools can be expensive, so hiring a professional might be more cost-effective if you suspect a severe leak.

Putty, Tape, Tools, and Materials to stop Water Pipe Leaks Fast.

When addressing pipe leaks, it's crucial to differentiate between temporary fixes and permanent solutions. Here's a breakdown of methods and materials for managing leaks:

Leak Repair

- Epoxy Putty: This is ideal for sealing holes or cracks in pipes. Ensure the pipe is dry before application for optimal adherence 2.

- Silicone Tape: Self-fusing silicone tape creates a waterproof layer perfect for temporary leak containment. It can be stretched tightly around the leak for a seamless seal.

- Repair Clamps: Utilize for more significant ruptures. A repair clamp with a neoprene rubber patch offers a quick fix.

- Plumbers Tape: Wrapping plumber's tape around pipe threads can prevent leaks at connections.

Leaking Pipe

- Gasket Kit or Blue Monster's Alpha Compression Tape: These are effective for long-lasting repairs on pinhole leaks.

- Pipe Clamps for Smaller Leaks are a more affordable yet permanent fix. They utilize rubber gaskets for a watertight seal.

- Professional Solutions: Professional plumbing services are available for leaks that defy DIY methods to ensure compliance with local codes and long-term durability.

It's essential to choose the right approach based on the severity of the leak and the pipe's material. Always prioritize safety and code compliance in your repair choices.

Sewer Pipe Leaking in Basement

A leaking sewer pipe in a building's basement can lead to significant problems if not addressed promptly. Sewer pipe leaks can occur for various reasons, such as corrosion, age, or damage from tree roots. Regardless of the cause, it is crucial to take immediate action to prevent further damage and health hazards.

A sewer pipe leak in the basement can accumulate wastewater, leading to foul odors, mold growth, and even structural damage. The stagnant water can seep into the walls and floors, causing them to weaken and deteriorate over time. Moreover, sewage in the basement poses serious health risks as it contains harmful bacteria and pathogens.

To mitigate the impact of a leaking sewer pipe in the basement, contacting Denver Sewer & Water at 720-935-6221 a top-rated Denver plumber immediately is essential. A skilled plumber like Denver Sewer & Water will assess the extent of the damage and determine the best course of action. Sometimes, a minor repair may be sufficient to fix the leak, while a complete replacement of the damaged pipe may be necessary for more severe situations.

In addition to repairing or replacing the leaking sewer pipe, addressing any water damage caused by the leak is crucial. This fix may involve drying the affected areas, removing mold or mildew growth, and restoring the damaged walls or floors. Hiring water leak professionals specializing in water damage restoration must ensure all traces of moisture are gone, and the affected areas are wholly fixed & repaired.

The leaking sewer pipe in the basement can have severe consequences if not dealt with promptly. Contacting a professional plumber when a sewer pipe leak is detected is vital to prevent further damage and health hazards. Taking immediate action will save you from costly repairs and ensure the safety and well-being of the building's occupants.

Sewer Pipe Leak Under Slab

A sewer pipe leak can be a significant issue, damaging your property and disrupting your daily life. To prevent further damage to the sewer line, it is essential to identify and fix the leak as soon as possible. One common location for sewer pipe leaks is under a building's slab foundation. These leaks can be challenging to detect, but several methods can help.

One way to find a sewer pipe leak under a slab is through a sewer line video inspection, which involves inserting a small camera into the sewer line to locate the exact location of the leak. The camera provides a live feed, allowing the plumber to visually inspect the inside of the pipe and identify any cracks or leaks. By pinpointing the leak's location, the plumber can determine the best action to repair it.

Another method for finding a sewer pipe leak under a slab is using specialized listening devices and detectors. These devices and sensors are designed to detect sound vibrations caused by water leaking from the pipe. By listening closely to these vibrations, plumbers can narrow down the leak's location and take appropriate repair steps. This method is beneficial in situations where visual inspection is not possible or inconclusive.

Sometimes, it may be necessary to access the sewer pipe directly to find the leak. This can involve excavating the area around the slab foundation to expose the pipe. Once the pipe is visible, plumbers can inspect it more closely for signs of leakage, such as water stains or moisture. This method is more invasive and time-consuming, but it may be necessary if other methods fail to locate the leak.

Finding a sewer pipe leak, especially under a slab, can be challenging. However, with the help of modern technology and professional expertise, it is possible to locate and repair these leaks efficiently. Whether through video inspection, listening devices, or direct access, identifying and fixing sewer pipe leaks is essential for maintaining the integrity of your property and ensuring a healthy living environment.

Denver homeowners and professionals often face a significant challenge in maintaining and repairing water pipes. My years of experience in the field have taught me that the key to effectively repairing water pipes is a comprehensive understanding of the materials used in their construction—metal pipes.

Water Pipe Leak Repair, Metal, Cast Iron, PVC, Copper, Plastic, Steel, Lead, Iron Pipe Leaks

Metal pipes, known for their durability, have been the mainstay of plumbing for decades. They include materials such as steel and copper, which I've found to resist corrosion and withstand high water pressure. However, metal pipes are not invulnerable and can deteriorate over time, especially if the water supply is highly acidic or exposed to external corrosive elements.

Due to their high-pressure tolerance, cast iron and ductile iron pipes are sturdy and often used for main water lines. Over the years, I've seen that these pipes can last long but are prone to rust and corrosion, leading to leaks or even pipe collapses. On the other hand, PVC and plastic pipes are lightweight, easy to install, and corrosion-resistant. They're commonly used in residential settings, although they are less tolerant of high temperatures and can become brittle.

Copper pipes are a popular choice for plumbing due to their longevity and resistance to bacteria. However, they can be susceptible to pinhole leaks caused by corrosion. Once shared, lead pipes are now known to pose serious health risks and are no longer installed in new buildings; instead, existing lead pipes are replaced with safer alternatives. Knowing these distinctions is critical to understanding the appropriate repair methods for each type of pipe.

Water Pipe Leak Damage

In my experience, water pipe damage can stem from many causes. Identifying the issue's root before attempting any repairs is crucial, as this will influence the approach and materials needed. Some of the most prevalent causes of water pipe damage include the natural aging process, corrosion, physical impacts, and environmental factors.

Corrosion is a frequent culprit, particularly with metal pipes. It can occur internally from the minerals in the water or externally due to environmental conditions. Corrosion gradually weakens the pipe walls, leading to leaks or bursts. I've also learned that high water pressure can strain pipes over time, causing joints to fail or pipes to crack.

Physical impacts, such as construction work or accidental strikes, can cause immediate damage to pipes. In colder climates, freezing temperatures are a common cause of pipe bursts. When water inside the pipes freezes, it expands, and the pressure can cause the pipe to crack. Additionally, tree roots can infiltrate and damage underground water pipes, leading to leaks or blockages.

Understanding these causes helps diagnose water pipe issues and determine the best repair action. It's a critical step in ensuring that the repair not only fixes the current problem but also helps prevent future occurrences.

Water pipe repair can be intricate and demands a systematic approach. The first step is to shut off the water supply to prevent further damage and allow for a safe repair environment. I've found that it's essential to assess the extent of the damage thoroughly, including checking for Pipe leaks, corrosion, and the overall condition of the pipes.

Once the damage is found, cleaning and preparing the affected area is next. It might involve removing rust or debris and ensuring the pipe surfaces are ready for the repair materials to adhere correctly. It's also essential to choose the correct repair method and materials based on the pipe type and the nature of the damage.

The pipe leak repair process varies, typically sealing leaks, replacing damaged pipe sections, or reinforcing weakened areas. After the repair, testing the system by slowly reintroducing the water supply and checking for leaks or other issues is vital. Taking these steps ensures a thorough and lasting repair, safeguarding my home against the consequences of water pipe damage.

Metal water pipes are renowned for their durability and longevity. Metals such as cast iron, copper, and steel have been the backbone of plumbing systems for decades. These metals have unique properties that make them suitable for specific situations.

Cast Iron Water Pipe Repair

Cast iron pipes have been a standard in the plumbing industry for centuries. Their durability is one of their most lauded characteristics. These pipes can last between 50 and 100 years if properly maintained. Their thick walls give them a sturdiness that is hard to match, making them suitable for main water lines and sewage systems.

Cast iron, for instance, is known for its excellent sound-dampening qualities and resistance to vibrations, making it ideal for underground systems.

Copper is praised for its antibacterial properties and flexibility, while steel pipes are strong and valued for their strength and resistance to shock and vibration.

However, metal pipes are not impervious to issues. Corrosion is a significant concern, especially in specific environments or when the water has a high mineral content.

Repairing metal water pipes requires understanding how to address these issues effectively without compromising the integrity of the plumbing system.

Iron is a recent addition to the family of iron pipes, developed as an improvement over traditional cast iron. The primary difference lies in its enhanced flexibility and strength, which comes from its unique graphite structure. Ductile iron pipes can bend without breaking, making them more resistant to external stress.

Copper Water Pipe Repair

Copper has been a preferred material for water pipes due to its longevity and resistance to bacteria. Its natural antibacterial properties make it an excellent choice for drinking water systems. Moreover, copper is relatively easy to work with, as it can be soldered to create watertight seals, and it is also highly recyclable, adding to its environmental appeal.

Steel Water pipe repair

Steel pipes, particularly stainless steel, are known for their exceptional strength and durability. For this reason, they are used in residential and commercial plumbing. Galvanized steel was once standard for water supply lines but has fallen out of favor due to its propensity to corrode over time.

Lead pipes are a significant health concern due to the risk of lead contamination in drinking water. Even small amounts of lead can be harmful, especially to children and pregnant women. As such, lead pipes are no longer being used in new water pipe installations, and many localities have programs to replace them.

1. Find Leaking Sink, Toilet, Shower, Bathtub Pipe

·Start by turning off the water supply to prevent further leakage. Locate the shut-off valves under sinks or toilets and turn them counterclockwise.

·Clean and dry the area around the leak. Removing accumulated water and drying the pipe ensures that materials like putty adhere correctly.

2. Putty, Rubber Patch, Tape Pipe Leak Repair

· A rubber Patch with a Hose Clamp can be a quick fix for minor leaks. Cut a rubber patch that is more significant than the leak, place it over the area, and secure it with a hose clamp, ensuring even tightening for a snug fit Slip Couplings offer a more permanent solution, beneficial for straight pipe sections. Clean the damaged area, apply PVC primer and glue, and fit the coupling over the pipe, ensuring a tight seal.

3. Final Pipe leak Checks and Cleanup

After applying the repair, check for moisture around the fixed area to ensure the leak is sealed 2.

Clean the workspace, removing any tools and soaking up leftover water. Disinfect cabinet surfaces if the leak was indoors to prevent mold growth

If you live in the City & County of Denver, Denver Water offers a free lead water test. Order a lead test request.

For more information, about lead in water testing, please visit the Colorado Department of Public Health and Environment

Leaking Sink Drain Pipe

As I maneuver through the complex world of plumbing, I've realized that understanding the various types of drain pipes is essential for any Denver homeowner or budding handyman. PVC, or polyvinyl chloride, is a staple in drain pipes, renowned for its durability and ease of use. But it's not alone; many other materials are used in creating the intricate networks that comprise our residential and commercial plumbing systems. These materials include cast iron, galvanized steel, copper, polyurethane, PEX, and clay, each with unique characteristics and applications. My journey into plumbing maintenance has taught me that knowing the ins and outs of these materials is crucial for effective repairs and maintenance.

I will take you through the intricacies of PVC and its fellow drain pipes, shedding light on their traits and how they fit into the larger picture of plumbing systems. Whether you're facing a minor leak or a significant overhaul, understanding what lies beneath your feet can make all the difference. I aim to arm you with the knowledge necessary to confidently tackle plumbing issues, ensuring your drainage system's longevity and reliability.

Remember that plumbing is not just a technical skill but also an art that requires patience, precision, and a willingness to learn. Let's begin our journey into the world of PVC and other drain pipes and discover how to master the art of repair and maintenance.

Repairing Drain Pipes Leak Repair, PVC, Cast Iron, Galvanized, Copper, Polyurethane, PEX, Clay Pipe Leak Repair

PVC Pipe Leak Repair

Polyvinyl chloride, or PVC, is a lightweight plastic famous for drain pipes. Its resistance to corrosion, ease of installation, and affordable cost make it a go-to option for many plumbers and DIY enthusiasts. PVC pipes are commonly white or cream and come in various sizes and thicknesses, making them suitable for different drainage needs.

Cast Iron Pipe Leak Repair

Cast iron drain pipes, known for their strength and durability, have been used for centuries. These incredibly robust pipes are ideal for underground installation where high pressure is expected. However, their weight and the potential for corrosion over time can make them less favorable than newer materials.

Galvanized Pipe Leak Repair

Galvanized pipes are steel pipes coated with zinc to prevent rusting. Once a standard in home plumbing, these pipes are less common in new installations but are still present in many older homes. Galvanization extends the life of steel pipes, but eventually, the zinc layer can erode, leading to corrosion.

Copper Pipe Leak Repair

Copper is one of the oldest materials used for plumbing and remains a reliable choice for drain pipes. It is resistant to corrosion, has natural antibacterial properties, and is recyclable, making it an environmentally friendly option. Copper pipes can last decades but are typically more expensive than other materials.

Polyurethane Pipe Leak Repair

Polyurethane pipes are a newer addition to the plumbing scene. They are flexible, making them great for applications where the pipes need to weave through obstacles. These pipes are also resistant to many chemicals and can handle various temperatures, making them versatile for residential and commercial use.

PEX Pipe Leak Repair

PEX piping is made from crosslinked polyethylene and has gained popularity due to its flexibility and ease of installation. It is often used for water supply lines but can also serve as a drain pipe. PEX is less prone to freezing and bursting, making it a solid choice in colder climates.

Clay Pipe Leak Repair

Clay drain pipes, often found in older homes and sewer systems, are made from natural clay. They are heavy and sturdy and can last long if not subjected to root intrusion or shifting soil. However, due to their brittleness and weight, they have primarily been replaced by more modern materials.

Each material has advantages and challenges. Understanding their properties is the first step in mastering the art of drain pipe repair and maintenance.

Repairing Other Drain & Sewer Pipes: Cast Iron, Galvanized, Copper, Polyurethane, PEX, Clay

Cast Iron Pipe Repair

Due to the material's weight and rigidity, cast iron pipe repair requires different techniques. One standard method involves using a snap cutter to remove and replace the damaged section with a PVC or cast iron pipe. A rubber coupling can join the new section to the existing pipes, creating a secure and watertight connection

Galvanized Pipe Repair

Galvanized pipes can be challenging to repair due to the potential for threading issues and corrosion. The best approach is often to cut out the damaged section and replace it with a more modern material like PVC or PEX. Using dielectric unions is crucial when connecting dissimilar metals to prevent galvanic corrosion.

Copper pipe repairs typically involve soldering a new pipe or a fitting over the damaged area. This process requires a propane torch and soldering materials. It's a delicate task that demands precision and safety precautions.

Polyurethane Pipe Repair

Polyurethane pipes can be fixed and repaired using specialized fittings and clamps designed for the material. Ensure the surface is clean and dry before applying the repair fittings to prevent leaks.

PEX Pipe Repair

Due to the material's flexibility, PEX pipe repairs are relatively straightforward. The bad part of the Pex line is replaced using PEX fittings and a crimp or clamp tool to secure the connections.

Clay Sewer Pipe Repair

Clay pipe repairs are more complex due to the material's brittleness. Often, the best solution is to replace the damaged clay pipe with a more resilient material like PVC, using flexible couplings to join the different materials.

Each type of pipe requires specific repair methods, and it's essential to understand the characteristics of the material you're working with to ensure a successful repair.

Drain Pipes Maintenance Repair

Preventive maintenance is critical to extending the life of drain pipes, regardless of the material. Regularly inspecting pipes for signs of wear and tear can help catch issues before they escalate. It's also important to be mindful of what goes down the drains; avoiding pouring grease, oils, and other clog-inducing substances can prevent blockages and stress on the pipes.

Avoiding exposure to extreme temperatures and direct sunlight can prevent the warping and degradation of PVC and other plastic pipes. Maintaining a stable environment for metal pipes, such as cast iron and copper, can help minimize the risk of corrosion. Installing water softeners in areas with hard water can also reduce mineral buildup inside the pipes.

Additionally, consider using drain guards and regularly cleaning out accessible traps and drains to catch debris. Cleaning the line can go a long way in preventing clogs and maintaining a clear pathway for waste and water. By taking these preventive measures, you can ensure the long-term health of your plumbing system.

Drain Pipe Leak & Drain Pipe Problems

Drain pipe repairs can be done using DIY methods, but calling a professional is sometimes the best way. If you encounter persistent leaks, significant water damage, or widespread corrosion, it's time to seek expert assistance. Additionally, if you're uncomfortable with the repair process or lack the necessary tools, relying on a professional plumber is safer.

Other signs warrant professional intervention include repeated clogs, sewage backups, and noticeable water pressure or quality changes. These issues may indicate more severe problems within your plumbing system that require specialized knowledge and equipment to diagnose and repair.

Professionals can also provide valuable insights into the overall condition of your pipes and suggest long-term solutions to prevent future issues. If in doubt, contact a licensed plumber to ensure your plumbing system is in good hands.

The Cost of Repairing PVC and Other Drain Pipes

The cost of repairing PVC and other types of drain pipes can vary widely depending on the extent of the damage, the type of repair needed, and the local market rates for plumbing services. PVC repairs are more affordable due to the low cost of materials and the ease of installation.

However, repairing metal pipes, such as cast iron or copper, can be more expensive due to the labor-intensive process and the cost of materials.

You must obtain multiple quotes from reputable plumbers to ensure you get a fair price for the repair work. Additionally, weigh the cost of repairs against the potential for future problems. Replacing old or severely damaged pipes may be more cost-effective in the long run than repeated repairs.

By understanding the factors contributing to repair costs, you can make informed decisions about your plumbing maintenance and budget accordingly.

What Makes PVC Pipes Stand Out?

For good reason, PVC pipes have taken the plumbing world by storm. Their standout features have made them a favored choice among professionals and homeowners. Firstly, PVC is highly resistant to corrosion, which can be a significant issue for metal pipes. This property alone extends the lifespan of PVC pipes considerably, reducing the need for frequent replacements.

Moreover, PVC pipes are lightweight, simplifying transportation and installation. This weight advantage also means less labor is required, which can lead to cost savings during installation. Another significant benefit is the material's versatility; PVC can handle both high-pressure applications and be used in various plumbing systems, from wastewater to potable water supply lines.

Lastly, PVC's smooth inner surface reduces the risk of clogs by facilitating a more consistent flow of water and waste. This smoothness also makes it easier to clean and maintain. For homeowners looking for a reliable, cost-effective solution for their plumbing needs, PVC pipes offer an outstanding balance of performance, durability, and affordability.

Common Problems with PVC and Other Drain Pipes

Despite the many advantages of PVC and other drain pipes, they are not without their issues. Over time, even the most durable materials can succumb to wear and tear, environmental factors, or unexpected damage. Joint problems may come from leaking pipes

leaks, cracks, clogs, and corrosion. These issues can stem from various causes, such as improper installation, ground movement, temperature changes, and the buildup of waste materials.

Leaks are often the most noticeable problem, as they can lead to water damage and increased utility bills. Cracks may develop due to physical stress or freezing temperatures, compromising the pipe's structural integrity. Clogs are another frequent concern, occurring when foreign objects or buildup obstruct the flow within the pipes. Lastly, corrosion, although less common in PVC, can be a significant problem for metal pipes, leading to leaks and reduced water quality.

Regular inspections and maintenance can help identify these problems early on, allowing for timely repairs and avoiding more severe damage. In the following sections, I'll guide you through repairing PVC and other drain pipes, ensuring you can address these issues effectively.

Repairing PVC Drain Pipes

- Initial Steps:

- Identify the damaged section of the PVC pipe. PVC is the most commonly used material in indoor wastewater systems because of its durability and soundproof qualities.

- Cut precisely through the pipe 1-2 inches beyond the damaged area, using a handsaw and miter box for accuracy.

2. Preparing and Replacing:

- Thoroughly clean and dry the ends of the pipe in the place where the cut to ensure a clean workspace

- Measure and cut the replacement section of the PVC pipe to the exact length needed

- Apply PVC primer solvent and solvent cement to the pipe ends and the replacement section, ensuring a secure and snug fit.

3. Finalizing the Repair:

- Allow the joint to cure for at least two hours before running water through the drain pipe to test for leaks.

- For underground repairs, remove the damaged section with a digger and slide the new pipe into place, securing it with collars tapped over with a hammer.

- Ensure a perfect fit and prevent future collapses by removing any blockages and using solid fittings.

By following these steps, homeowners can effectively repair drain pipes, maintaining the functionality of their wastewater systems.

Repairing Copper Pipes in your Denver home

As a Denver homeowner, it is essential to understand how to repair copper pipes and prevent water leaks effectively. Copper pipes are the norm used in plumbing systems due to their durability and resistance to corrosion. However, these pipes can develop leaks over time, leading to water damage and costly repairs. In this expert guide, I will provide practical solutions to repair copper pipe leaks and share preventive measures to avoid water leaks altogether.

Common issues with Copper Pipes

In repairing copper pipe leaks, we must familiarize ourselves with the common issues that can arise. Copper pipes are susceptible to specific problems, such as pinhole leaks and wear and tear in old pipes.

Pinhole leaks are tiny holes that develop in copper pipes due to corrosion. These leaks can lead to significant water damage if not addressed promptly. Additionally, older copper pipes may show signs of wear and tear, such as discoloration, corrosion, or weakened joints. Identifying these issues early on can help prevent extensive damage and costly repairs.

Repairing Pinhole leaks in Copper Pipes

One such solution is epoxy putty or pipe repair tape. These temporary fixes for copper pipe water leaks, called pinhole leaks, can provide a quick and efficient solution. However, it is essential to note that these methods are not as durable as soldering and may require periodic monitoring.

Soldering Copper Pipe Leaks

Soldering is a reliable and long-lasting method for repairing copper pipe leaks. Here is a step-by-step guide to help you through the process:

1. Prepare the area: Start by turning off the water supply and draining the affected pipe. Clean the damaged area using sandpaper or a wire brush to remove any corrosion or debris.

2. Apply flux: Apply a thin flux layer to the cleaned area. Flux helps remove impurities and promotes proper solder adhesion.

3. Heat the joint: Use a propane torch or a soldering iron to heat the joint evenly. Once the joint reaches the right temperature, apply solder, allowing it to flow into the gap and create a strong bond.

4. Inspect and test: After the solder has cooled, inspect the repaired area for leaks. Turn on the water supply and observe the joint for any signs of water leakage.

Signs of wear and tear in old Copper Pipes

Old copper pipes are more susceptible to wear and tear, which can result in leaks. It is crucial to identify signs of deterioration to determine if repair or replacement is necessary. Here are some signs that your old copper pipes may need attention:

1. Discoloration: If your copper pipes have turned green or have dark spots, it indicates corrosion and potential leaks.

2. Weakened joints: Check your copper pipe system for loose or weakened joints. These can be signs of pipe deterioration and impending leaks.

3. Frequent leaks: If you experience recurring leaks in your old copper pipes, they may indicate they have reached their lifespan and need replacement.

Replacing old Copper Pipes Instead of Repairing Them

While repairing copper pipes is often a viable solution, there are instances where replacement may be more appropriate. Here are a few situations when replacing old copper pipes is recommended:

1. Extensive corrosion: Multiple repairs may become costly and time-consuming if your copper pipes show extensive corrosion and damage. In such cases, replacing all the pipes can provide a more reliable long-term solution.

2. Frequent leaks may indicate widespread pipe degradation if you consistently experience leaks in different sections of your copper pipe system. Replacing the entire system could help avoid future leaks and save you from frequent repairs.

3. Outdated plumbing system: If your home has an outdated plumbing system with old copper pipes, it may be more cost-effective to replace the entire system rather than repair individual leaks. Upgrading to modern plumbing materials can provide better longevity and performance.

At Denver Sewer & Water, we recognize that your time is valuable, which is why we’re happy to negotiate a time that works for you, and our skilled Denver plumbers always show up on time. Our courteous and respectful Denver plumbers strive to quickly fix your Denver homes sewer, water, drain & copper line leaks repaired.

Denver Sewer & Water is a fully licensed and insured sewer & water, drain & copper line leaks fixes fast in Denver, CO, offering quality workmanship and ensuring your safety and peace of mind. We guarantee you’ll be satisfied with our sewer, water, drain, line repairs which is why we’re pleased to offer a 5-year transferable warranty on all of our work call 720-935-6221. When you need a Denver plumbing company that gets the job done right the first time, so you don’t have to hassle with ongoing issues and expenses, the experts at Denver Sewer & Water are the best choice for water line repair in Denver.

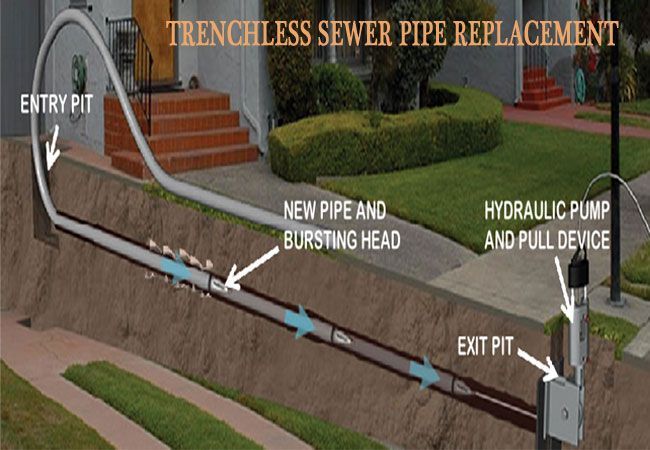

Whether you need partial water line repairs or drain or sewer repairs, trenchless sewer line replacement, repair, or full excavation, Denver Sewer & Water finds solutions for stopping water line and drainage problems before they start. Our service includes a complete sewer & drain scope examination. Call-720-935-6221